Ogwe osisi → ịgbado oyi → nkwonkwo → ịgbado ọkụ → isi nhazi → ọgwụgwọ okpomọkụ → nhazi nke abụọ (ihe akaebe) → nyocha. Welding na okpomọkụ ọgwụgwọ bụ isi usoro na mmepụta nke Ngwuputa gburugburu njikọ ígwè yinye, nke na-emetụta kpọmkwem ngwaahịa àgwà. Usoro ịgbado ọkụ nke sayensị nwere ike melite mkpụrụ ma belata ọnụ ahịa mmepụta; Usoro ọgwụgwọ okpomọkụ kwesịrị ekwesị nwere ike inye egwuregwu zuru oke na ihe onwunwe ma melite àgwà ngwaahịa.

Iji hụ na ịgbado ọkụ nke Ngwuputa gburugburu njikọ ígwè yinye, akwụkwọ ịgbado ọkụ na-eguzogide butt ịgbado ọkụ ewepụwo. Flash butt ịgbado ọkụ bụ ọtụtụ ebe n'ihi na ya elu ogo nke akpaaka, obere ọrụ ike, kwụsiri ike ngwaahịa àgwà na ndị ọzọ pụtara ìhè uru.

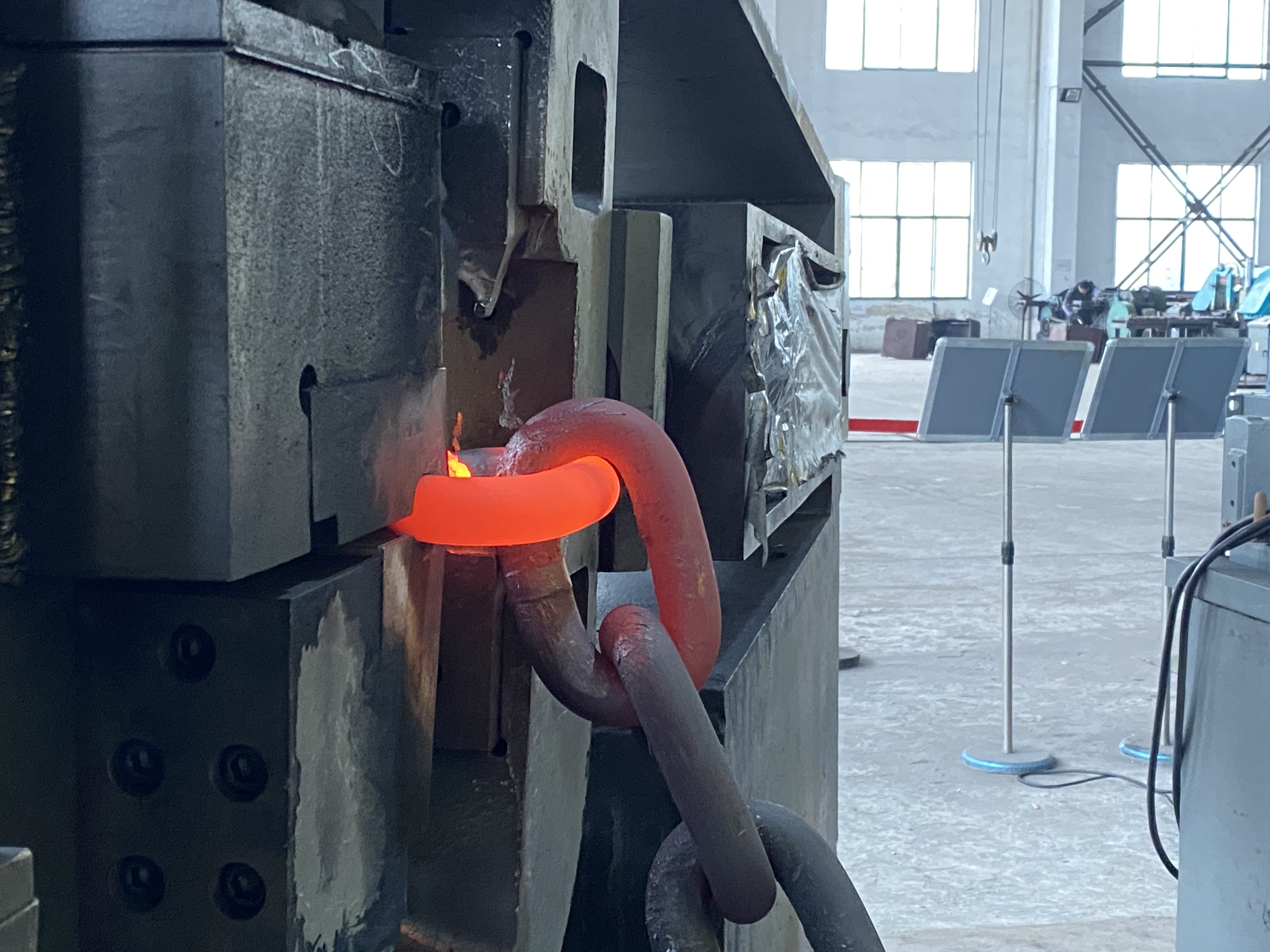

Ka ọ dị ugbu a, a na-ejikarị usoro ịgbanye ọkụ na-ajụkarị induction kpo oku na-aga n'ihu na usoro ikpo ọkụ na ọgwụgwọ ọkụ nke ngwungwu nchara nchara. Ihe dị mkpa nke ikpo ọkụ na-ajụkarị ugboro ugboro bụ na a na-akpali usoro ihe omimi nke ihe n'okpuru oghere electromagnetic, na molecule ahụ na-enweta ume ma na-agbakọta iji mepụta okpomọkụ. Mgbe a na-eduzi ọgwụgwọ okpomọkụ nke ọkara ugboro ugboro, a na-ejikọta inductor na ọkara ugboro na-agbanwe ugbu a nke oge ụfọdụ, na workpiece na-aga n'otu ọsọ ọsọ na ihe mmetụta, nke mere na a ga-emepụta induction ugbu a na otu ugboro na ntụgharị ihu na workpiece, nke ga-agbanwe ike eletrik n'ime ike ọkụ, na workpiece ga-ewe iwe ọkụ na okpomọkụ nke chọrọ site n'ibelata oge na tempering.

Igwe ọkụ induction ugboro ugboro nwere uru nke ngwa ngwa kpo oku, obere oxidation, ezigbo quenching Ọdịdị na nha ọka austenite mgbe emenyụchara, nke na-eme ka ike na ike nke njikọ njikọ ahụ dịkwuo mma. N'otu oge ahụ, ọ nwekwara uru nke ịdị ọcha, ngbanwe dị mfe na mmepụta mmepụta dị elu. Na tempering ogbo, elu tempering okpomọkụ na yinye njikọ ịgbado ọkụ mpaghara nwere ike iwepụ quenching esịtidem nchegbu na a obere oge, nke nwere mmetụta dị ukwuu na-emeziwanye plasticity na siri ike nke yinye njikọ ịgbado ọkụ mpaghara na-egbu oge mmalite na mmepe nke cracks. Ọnọdụ okpomọkụ dị n'elu ubu dị ala, na ike siri ike dị elu mgbe ọ na-ewe iwe, bụ nke na-enye aka na-eyiri njikọ njikọ na usoro nke na-arụ ọrụ na megide nkwụsị n'etiti njikọ njikọ na sprocket meshing.

Oge nzipu: Mee-10-2021