I. Mkpa ọ dị ịhọrọ agbụ na agbụ nke ziri ezi

N'ụlọ ọrụ simenti, igwe mbuli bọket dị oke mkpa maka ibu nnukwu ihe ndị na-emebi emebi dị ka clinker, limestone, na ciment kwụ ọtọ.Agbụ njikọ na okirikirina-agbasi ike n'ibu nrụgide, na-eme ka ha chepụta na mmepụta àgwà akara dị mkpa maka ịrụ ọrụ ịga nke ọma. Nke a bụ ihe kpatara ịhọrọ akụrụngwa ziri ezi dị mkpa yana ka SCIC si agba nke a:

1. Ike ibu ibu:Agbụ na agbụga-anagide ibu tensile dị elu yana mmetụta ujo site na mmegharị ịwụ na-aga n'ihu. Ihe ndị na-adịghị mma nwere ike ibute ọdịda mberede, na-eduga n'oge ọdịda, ihe egwu nchekwa, na nrụzi dị oke ọnụ. Ndabere nke SCIC na ụkpụrụ DIN na-eme ka a hụ na ngwaahịa anyị na-egbo mkpa ike dị mkpa, dị ka ike mgbawa akọwapụtara nke 280-300 N/mm².

2. Wear Resistance: The abrasive ọdịdị nke simenti ihe accelerates eyi na mbuli components. Agbụ ígwè siri ike (ihe ruru 800 HV) na agbụ (ihe ruru 600 HV) na-enye elu na-adịgide adịgide iji guzogide abrasion, na-ejigide isi ike iji gbochie mgbawa. Usoro carburizing ziri ezi nke SCIC na-enweta ihe achọrọ 10% carburizing ọkpụrụkpụ yana 5-6% ịdị omimi siri ike dị irè, na-ahụ na arụmọrụ ogologo oge.

3. Ụkpụrụ Nkwekọrịta: Nrube isi na DIN 764, DIN 766, DIN 745, na DIN 5699 na-ekwe nkwa naagbụ na agbụzute akara nrịbama ụlọ ọrụ maka akụkụ, akụrụngwa akụrụngwa na ntụkwasị obi. Ọkachamara SCIC n'imezu ụkpụrụ ndị a na-eme ka ịdị mma na-agbanwe agbanwe nke ahaziri maka ngwa ọrụ dị arọ.

4. Njikwa ogo mmepụta ihe: njikwa mma siri ike nke SCIC-site na nhọrọ ihe ruo nleba anya ikpeazụ-na-ebelata ntụpọ ma na-eme ka o doo anya na nha nha, ike siri ike na ike. Ike a na-ebelata ohere nke ọdịda n'okpuru ọnọdụ siri ike nke ụlọ ọrụ ciment.

Ịhọrọ nke ziri eziagbụ na agbụdị oke mkpa maka arụmọrụ na nchekwa nke igwe mbuli elu ịwụ gị. Na SCIC, a na-emepụta ngwaahịa anyị ma rụpụta ya iji zute ụkpụrụ DIN siri ike, na-ahụ na ha nwere ike iguzogide ibu dị arọ na ihe abrasive na-emekarị na ụlọ ọrụ ciment. Site na njikwa mma anyị siri ike, ị nwere ike ịtụkwasị obi na agbụ na agbụ anyị ga-enye arụmọrụ a pụrụ ịdabere na ya, na-ebelata ihe ize ndụ nke ọdịda na-atụghị anya ya na ụgwọ ọrụ.

II. Ịhazi ike na ike n'oge nrụpụta

Inweta ike nke elu nke ndị ahịa akọwapụtara (800 HV maka agbụ, 600 HV maka agbụ), ọkpụrụkpụ carburizing (10% nke dayameta njikọ), ịdị omimi siri ike dị irè (550 HV na 5-6% nke dayameta), na imebi ike (280-300 N / mm²) chọrọ nlezi anya nke ọma n'etiti ike na ike. Nke a bụ ka SCIC si eme nke a site na nhọrọ ihe, ọgwụgwọ okpomọkụ, na carburizing:

Usoro nrụpụta igodo

1. Nhọrọ ihe:A na-ahọrọ ígwè dị elu nke carbon ma ọ bụ alloy maka ikike ha nwere ịzaghachi na carburizing na quenching, na-enye ma ike elu elu na isi ike.

2. Ịgba ọkụ:Carburizing na-agbasa carbon n'ime nchara nchara ka ọ dịkwuo ike. Maka njikọ agbụ nke nwere dayameta 20 mm;Omimi Carburizing: 10% nke 20 mm = 2 mm;Omimi siri ike dị irè: 5-6% nke 20 mm = 1-1.2 mm na 550 HV;Nke a na-emepụta elu siri ike, nke na-agaghị eyi mgbe ị na-echekwa isi ductile iji nweta ibu dị ike.

3. Ọgwụgwọ okpomọkụ:Quenching: Mgbe carburizing gasịrị, a na-emenyụ ihe ndị ahụ iji kpọchie n'elu ike (800 HV maka agbụ, 600 HV maka agbụ);Okpomọkụ: iwe ọkụ a na-achịkwa (dịka ọmụmaatụ, na 200–250°C) na-edozi njirimara nke isi, na-eme ka ike siri ike na ike mgbaji achọrọ nke 280–300 N/mm². Iwebiga oke iwe na-ebelata isi ike, ebe iwe iwe na-etinye ihe egwu nhịkọ.

4. Iwu ịhazigharị: Isi ike: Isi ike dị elu na-eguzogide iyi site na ihe abrasive;Ike: Isi isi ike na-egbochi mgbaji mgbaji n'okpuru ibu ntanye.SCIC na-achịkwa omimi carburizing na oke iwe iji zere nrụrụ oke oke mgbe ị na-ezute nkọwa ndị ahịa.

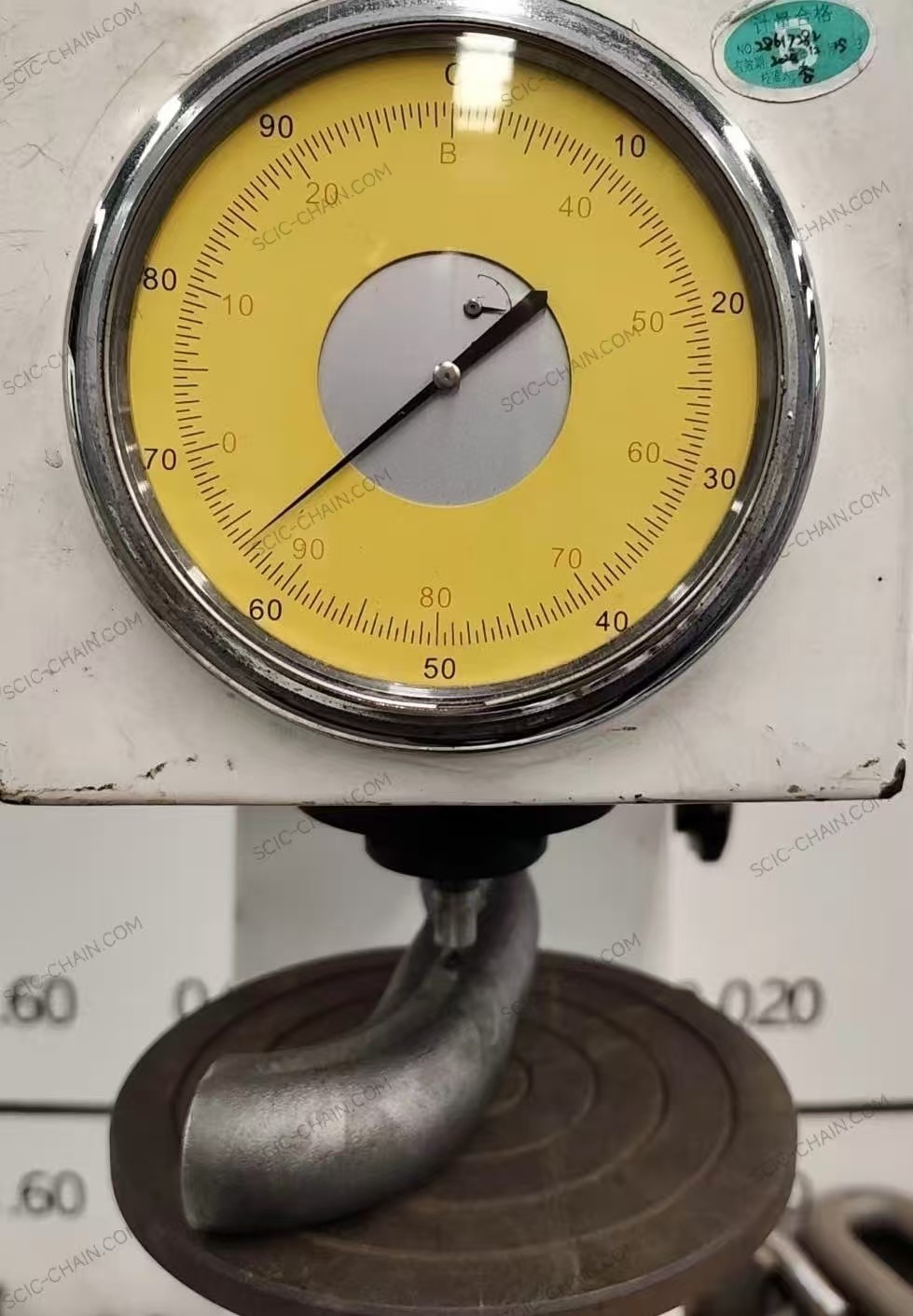

(njikọ yinye na elu carburized siri ike)

(njikọ yinye na elu carburized siri ike, mgbe agbajichara ule ike)

A na-achịkwa usoro mmepụta anyị nke ọma iji nweta nguzozi zuru oke n'etiti ike na ike. Site kpọmkwem carburizing na okpomọkụ ọgwụgwọ, anyị hụ na anyịagbụ na agbụnwee elu siri ike, nke na-agaghị eyi mgbe ị na-ejigide isi ihe siri ike iji jikwaa ibu dị ike na arụ ọrụ gị. Ntụle a dị oke mkpa maka ịbawanye ogologo ndụ yana ntụkwasị obi nke akụrụngwa.

III. Ịkwado ogologo ndụ site na ịrụ ọrụ na mmezi

Ọbụna naagbụ na agbụ dị elu, ịrụ ọrụ kwesịrị ekwesị na mmezi dị mkpa iji mee ka ogologo ndụ dị elu na igwe ụlọ ọrụ ciment factory bucket . SCIC na-enye ndị ahịa ntuziaka ndị a:

Ntuziaka nlekọta

1. Nleba anya mgbe niile:Leleeagbụ na agbụmaka akara iyi, dị ka elongation (dịka ọmụmaatụ> 2-3% nke ogologo mbụ), nrụrụ, ma ọ bụ mgbawa elu. Nchọpụta mbụ na-egbochi ọdịda.

2. mmanu mmanu:Tinye mmanu na-ekpo ọkụ na oke okpomọkụ iji belata esemokwu na iyi. Rie mmanu ọ bụla 100-200 awa ọrụ, dabere na ọnọdụ.

3. Nleba anya nhụsianya:Nọgide na-enwe oke mgbakasị ahụ n'agbụ ka ịzenarị ike ọgwụgwụ (na-akpata ịjagharị) ma ọ bụ imebiga ihe ókè (na-abawanye iyi). Gbanwee nkọwapụta SCIC ọ bụla.

4. Ndochi n'oge:Dochie ihe ndị eyighị ma ọ bụ mebiri emebi ozugbo iji gbochie ọdịda cascading. Dịka ọmụmaatụ, a ga-atụgharị eriri nke nwere nkwarụ ozugbo.

5. Omume kacha mma arụ ọrụ:Na-arụ ọrụ n'ime oke imewe (dịka ọmụmaatụ, zere ibubiga ihe karịrị 280-300 N/mm² ike imebi ike) iji belata nchekasị.

Iji mee ka ogologo ndụ nke agbụ gị na agbụ gị dị elu, soro omume ndị a: na-enyocha mgbe niile maka iyi uwe, hụ na mmanu mmanu mmanu mmanu mmanu mmanu mmanu mmanu mmanu mmanu mmanu mmanu mmanu mmanu mmanu mmanu mmanu mmanu mmanu mmanu mmanu mmanu mmanu mmanu mmanu mmanu mmanu mmanu mmanu mmanu mmanu mmanu mmanu mmanu mmanu mmanu mmanu mmanu , na-eleba anya n'agbụ ígwè , na dochie mebiri emebi ngwa ngwa. Site n'ịgbaso ntuziaka ndị a na ịrụ ọrụ n'ime oke nhazi, ị nwere ike ịgbatị ntụkwasị obi na arụmọrụ nke igwe mbuli bọket gị.

Ọmụmụ ihe: Mmetụta ụwa n'ezie

Ọnọdụ:

Otu ụlọ ọrụ ciment na-eche ihu na-ada ụda njikọ njikọ okirikiri ugboro ugboro, na-agbadata awa 10 kwa ọnwa n'ihi ụdọ nwere naanị 600 HV siri ike na omimi carburizing na-emighị emi. Nke a mere ka ọnụ ahịa nrụzi dị elu na mmepụta efu.

Ngwọta:

Ụlọ ọrụ mmepụta ihe ahụ nakweere ụdọ njikọ okirikiri SCIC siri ike:

- Oke: 30mm dayameta, 800 HV elu ike, 3mm carburizing omimi, 1.8mm ike ike na 550 HV, 290 N / mm² imebi ike.

- Ndozi: nyocha kwa izu abụọ, mmanu mmanu ọ bụla awa 150, yana mgbanwe mgbanwe.

(njikọ yinye nwere mma carburizing omimi na dayameta njikọ 10%)

IV. Nsonaazụ

1. Oge nkwụsị: Belata 80% (ruo 2 awa / ọnwa).

2. Ndụ ndụ: Chains dịruru ọnwa 18 (vs. 6 ọnwa gara aga).

3. Nchekwa ọnụ: Ọnụ ego nlekọta na-agbada site na 50% kwa afọ.

Nke a na-egosi ka akụrụngwa dị elu nke SCIC na ntụzịaka nrụzi na-esi enweta uru a na-ahụ anya.

V. Mmechi

1. Ịhọrọ akụrụngwa ziri ezi:Agbụ na agbụ na-adabara SCIC's DIN, kwadoro site na nhazi dị elu na njikwa mma, hụ na nchekwa na arụmọrụ dị na ụlọ ọrụ ciment factory bucket .

2. Ịhazi ike na ike: Anyị kpọmkwem n'ichepụta usoro izute ahịa nkọwa, na-anapụta eyi iguzogide na ibu-ebu ike.

3. Na-eme ka ndụ dịkwuo elu: Ntuzi nlekọta na-arụ ọrụ na-eme ka ntụkwasị obi dị ogologo oge.

Site na imekọ ihe ọnụ na SCIC, ndị ahịa na-enweta ụdọ na agbụ nke akọpụtara nke ọma, ahaziri maka mkpa ha, yana atụmatụ egosipụtara na-akwado iji kwalite arụmọrụ yana belata ọnụ ahịa.

Oge nzipu: Eprel-21-2025